Key Machines

Latest News

Cooking Oil Production Line

Palm Oil Refinery Plant and Fractionation Processing Line Machinery

Sinoder is offering a complete choice of products which include Palm Oil Refining Plant, Palm Oil Refining System and Palm Oil Refining Equipments to the customers. We assist in complete Palm Oil Refining Solutions from start to end. We have the expertise to provide the cost effective palm oil refineries for the crude oil.

The red palm oil is the oil obtained from the palm fruits of the oil palm. The beta-carotene and carotene content present in the fruit is responsible for the reddish color of the oil.

The red palm oil is the oil obtained from the palm fruits of the oil palm. The beta-carotene and carotene content present in the fruit is responsible for the reddish color of the oil.

We're here to help: Easy ways to get the answers you need.

Product Introduction

We are leading manufacturers and exporters of Vegetable Oil Refinery Plants, Edible Oil Refinery Plants and Palm Oil Refinery Plants. We supply and export the complete refinery plant and make this project a success for the customer.

Sinoder is offering a complete choice of products which include Palm Oil Refining Plant, Palm Oil Refining System and Palm Oil Refining Equipments to the customers. We assist in complete Palm Oil Refining Solutions from start to end. We have the expertise to provide the cost effective palm oil refineries for the crude oil.

The red palm oil is the oil obtained from the palm fruits of the oil palm. The beta-carotene and carotene content present in the fruit is responsible for the reddish color of the oil.

Palm Kernel Oil Refining is required to make the kernel oil edible. The kernel oil when extracted from the kernel oil mill plant is full of impurities and other substances. We manufacture superior range of palm kernel oil refining systems.

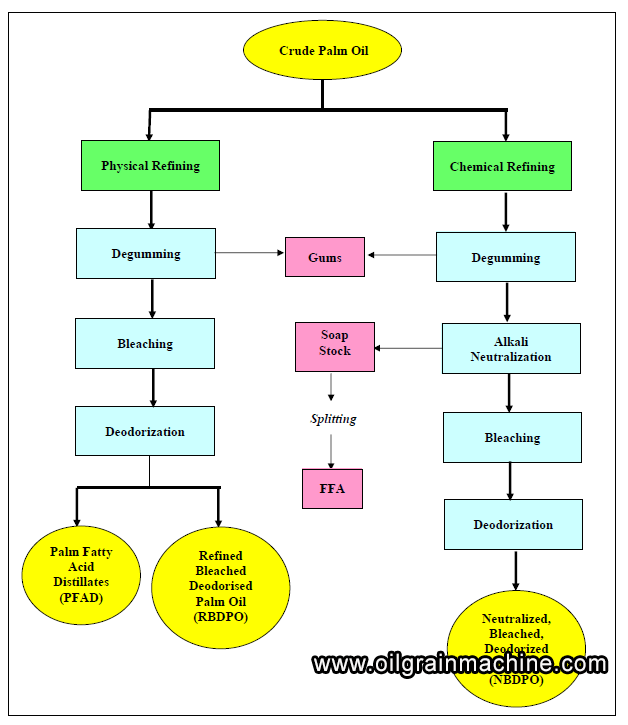

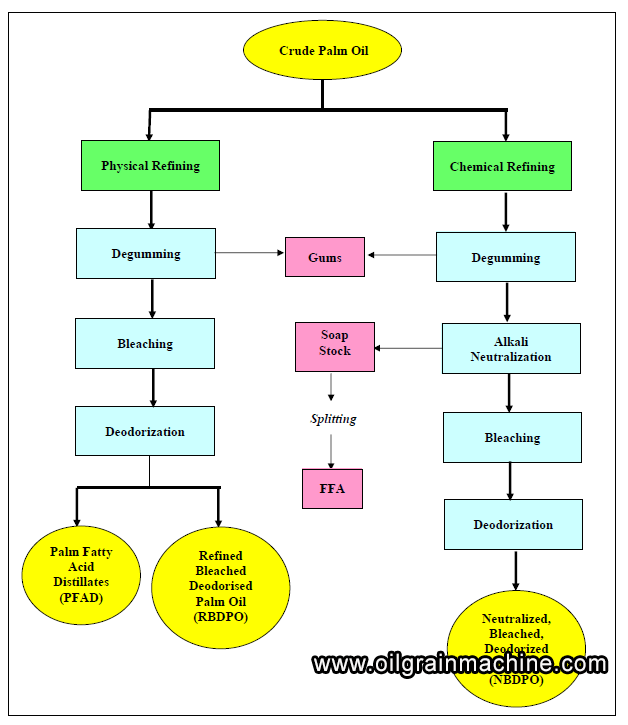

Crude Palm Oil Refinery Flow

Palm Oil Refining Line Plant

The Palm Kernel Oil Refinery Equipments have the following:

Equipment and System for Neutralization

Equipment and System for Water Washing

Equipment and System for Bleaching

Equipment and System for Vacuum Drying

Equipment and System for Deodorizing

Equipment and System for Filtering

Sinoder is offering a complete choice of products which include Palm Oil Refining Plant, Palm Oil Refining System and Palm Oil Refining Equipments to the customers. We assist in complete Palm Oil Refining Solutions from start to end. We have the expertise to provide the cost effective palm oil refineries for the crude oil.

The red palm oil is the oil obtained from the palm fruits of the oil palm. The beta-carotene and carotene content present in the fruit is responsible for the reddish color of the oil.

Palm Kernel Oil Refining is required to make the kernel oil edible. The kernel oil when extracted from the kernel oil mill plant is full of impurities and other substances. We manufacture superior range of palm kernel oil refining systems.

Crude Palm Oil Refinery Flow

Palm Oil Refining Line Plant

The Palm Kernel Oil Refinery Equipments have the following:

Equipment and System for Neutralization

Equipment and System for Water Washing

Equipment and System for Bleaching

Equipment and System for Vacuum Drying

Equipment and System for Deodorizing

Equipment and System for Filtering

Technical parameters

PALM OIL FRACTIONATION PLANT

Fractionation Plant is a part of the oil modification procedure. Some of the vegetable oils need to be physically or chemically altered so that there is change in the properties of the oil. We have developed unique fractionation plants and systems for the oil modification. Our Fractionation plants are useful in the Palm Oil Refinery Plants to refine and process the palm oil.

The Palm Oil Fractionation is used in the Palm Oil Refinery Plants. Fractionation process consists of a controlled cooling of the oil, in order to make it crystallized. We supply the fractionation plants with our all the Palm Oil Refinery Plants.

This Dry Fractionation is performed through batch crystallization of oil without using additives by controlled cooling and subsequent continuous filtration of that oil. Palm Oil Fractionation is very important part of the refinery. It is to be carried out so that to separate the solid portion and the liquid portion of the oil.

The process of fractionation can be applied to:

Cotton seed oil

Shea butter

Sal fat

Mango kernel oil

Palm oil

Rice bran oil

Palm kernel

Sunflower oil

PALM OIL FRACTIONATION PLANT

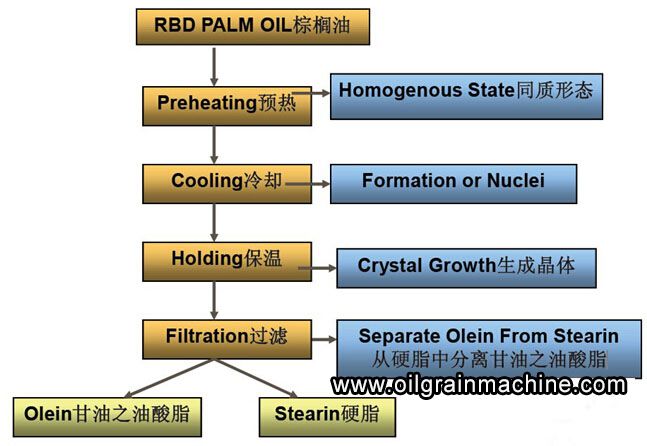

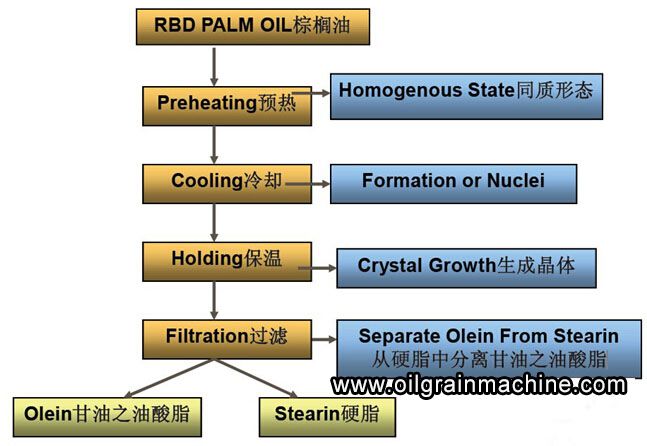

The process consists of the five steps listed below:

Heating the feed oil

Formation of crystals by controlled cooling

Crystal growth

Maturation of crystals

Filtration to separate Olein and Stearine

Generally R.B.D. Palm oil is used for fractionation. For getting R.B.D. Palm oil, crude palm oil is refined, bleached and deodorized.

After getting the desired quality of R.B.D. Palm oil, it is pre-heated up to 70oC to give a homogeneous mass with no solid portion. Sinoder has provided a PHE using which the oil temperature can be maintained as desired.

Oil is fed continuously and the flow rate is controlled with the help of an oil flow control valve. In the 1st and 2nd crystallizers cooling is done by ordinary water, which is available directly from the cooling tower at a temperature of 32°C.

Cooling in the 3rd and 4th crystallizers is done by chilled water which is available from the vapor absorption chiller at 7oC.

During the cooling sequence, samples were taken at regular intervals from the crystallizer and analyzed for their physical behavior. The physical properties of the olein and stearin fractions, such as cloud point, slip melting point and solid fat content, were found to be dependent on the crystallization temperature.

On flow crystallization method will ensure the cooling and crystal formation has been attained in all the crystallizers and continuing the flow through compensator to the filter by gravity.

Oil from the compensator is first filled in the membrane filter by gravity and after attaining a pressure of 1.5 – 2 kg/cm2 the filter pump is started. For filtering the olein from the filter press all operations such as opening, closing, squeezing and washing and discharge of the stearine to the stearine melting tank are automated and computerised.

Fractionation Plant is a part of the oil modification procedure. Some of the vegetable oils need to be physically or chemically altered so that there is change in the properties of the oil. We have developed unique fractionation plants and systems for the oil modification. Our Fractionation plants are useful in the Palm Oil Refinery Plants to refine and process the palm oil.

The Palm Oil Fractionation is used in the Palm Oil Refinery Plants. Fractionation process consists of a controlled cooling of the oil, in order to make it crystallized. We supply the fractionation plants with our all the Palm Oil Refinery Plants.

This Dry Fractionation is performed through batch crystallization of oil without using additives by controlled cooling and subsequent continuous filtration of that oil. Palm Oil Fractionation is very important part of the refinery. It is to be carried out so that to separate the solid portion and the liquid portion of the oil.

The process of fractionation can be applied to:

Cotton seed oil

Shea butter

Sal fat

Mango kernel oil

Palm oil

Rice bran oil

Palm kernel

Sunflower oil

PALM OIL FRACTIONATION PLANT

The process consists of the five steps listed below:

Heating the feed oil

Formation of crystals by controlled cooling

Crystal growth

Maturation of crystals

Filtration to separate Olein and Stearine

Generally R.B.D. Palm oil is used for fractionation. For getting R.B.D. Palm oil, crude palm oil is refined, bleached and deodorized.

After getting the desired quality of R.B.D. Palm oil, it is pre-heated up to 70oC to give a homogeneous mass with no solid portion. Sinoder has provided a PHE using which the oil temperature can be maintained as desired.

Oil is fed continuously and the flow rate is controlled with the help of an oil flow control valve. In the 1st and 2nd crystallizers cooling is done by ordinary water, which is available directly from the cooling tower at a temperature of 32°C.

Cooling in the 3rd and 4th crystallizers is done by chilled water which is available from the vapor absorption chiller at 7oC.

During the cooling sequence, samples were taken at regular intervals from the crystallizer and analyzed for their physical behavior. The physical properties of the olein and stearin fractions, such as cloud point, slip melting point and solid fat content, were found to be dependent on the crystallization temperature.

On flow crystallization method will ensure the cooling and crystal formation has been attained in all the crystallizers and continuing the flow through compensator to the filter by gravity.

Oil from the compensator is first filled in the membrane filter by gravity and after attaining a pressure of 1.5 – 2 kg/cm2 the filter pump is started. For filtering the olein from the filter press all operations such as opening, closing, squeezing and washing and discharge of the stearine to the stearine melting tank are automated and computerised.

FAQ

Vegetable Oil Refinery Plant

We introduce ourselves as the leading manufacturers and exporters of different types of Oil Refinery Plants. We supply the complete machinery and equipments and take responsibility for the entire plant start-up. The range of products at Sinoder include the:

Vegetable Oil Refinery Line

Edible Oil Refinery Line

Complete Oil Refining Systems

Equipments and Machinery for Oil Processing

Oil Mill Machinery

Palm Refining Project

We manufacture and provide the complete Vegetable Oil Refinery Plant. Our refinery plant is a long lasting system for refining the crude vegetable oil. Our vegetable oil refinery can process oils such as sunflower oil, soybean oil, rice bran oil, copra oil, peanut oil, palm kernel oil, mustard oil, cottonseed oil etc.

If you are looking to setup the Vegetable Oil Refinery Plant then contact SINODER and email us your requirement and we shall guide you in the entire project setup.

We introduce ourselves as the leading manufacturers and exporters of different types of Oil Refinery Plants. We supply the complete machinery and equipments and take responsibility for the entire plant start-up. The range of products at Sinoder include the:

Vegetable Oil Refinery Line

Edible Oil Refinery Line

Complete Oil Refining Systems

Equipments and Machinery for Oil Processing

Oil Mill Machinery

Palm Refining Project

We manufacture and provide the complete Vegetable Oil Refinery Plant. Our refinery plant is a long lasting system for refining the crude vegetable oil. Our vegetable oil refinery can process oils such as sunflower oil, soybean oil, rice bran oil, copra oil, peanut oil, palm kernel oil, mustard oil, cottonseed oil etc.

If you are looking to setup the Vegetable Oil Refinery Plant then contact SINODER and email us your requirement and we shall guide you in the entire project setup.