Latest News

Cooking Oil Production Project

FFB of Oil Palm into CPO Palm Oil Mill Production Line Project

FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Project

Sinoder Group Supply Complete FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Threshing & Extraction Processing & Refining & Fractionation Machinery and Solution with Full Around Technology and Service! -- Sinoder Engineering FFB into CPO Production Line Mill Plant

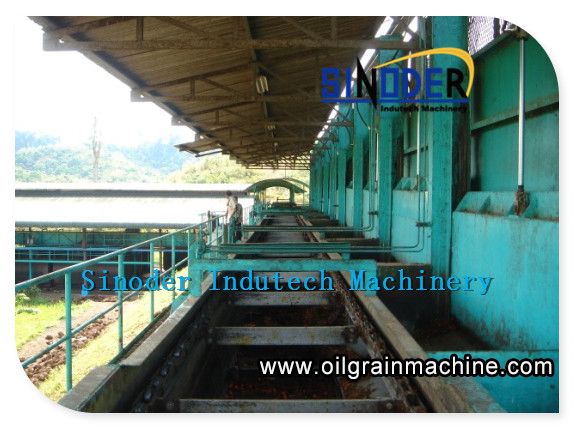

FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Oil Mill Plant

Palm Oil Mill System Introduction:

1. Raw materials storage section: Fresh palm fruit bunch must be first measurement recorded by the pound into the plant, then unloaded to loaded fruit slopes and stored.

2. Sterilizing section: fresh palm fruit bunch are airtight sterilized in sterilizer. The purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase; easy threshing machinery; pretreatment peel, prepared for the follow-up processing; pre-conditioning stone, reducing the damage kernel.

3. Threshing section: The purpose of threshing is to separate oil palm fruit from the fruit bunch through strong vibration, Threshing equipment is revolving drum thresher. The separated oil palm fruit is ejected then into the pressing section. Empty fruit bunch be ejected to the yard from the other side of the revolving drum, or shipped out from the plant as palm orchards slipcover to recycling use, or burning in the locale as fertilizer for agricultural land.

4. Pressing section: Before pressed, oil palm fruit first be carried out cooking, sterilized fruit must be re-heated to make the pulp soft and damage pulp cell structure. Then enter into continuous screw press for pressing. After pressing, oil palm fruit is divided into two parts: oil, water, solid impurities mixture and the press cake (fiber and nuclear). Oil, water, solid impurities mixture inflow to oil purification section by the crude oil gutter; pressed cake into the fiber- recovery section by breaking screw conveyor.

5. Clarification section: Machine-pressed crude oil first diluted with water washing, the fiber material removed from the oil through settlement and filtration, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. Through centrifugal separation and vacuum drying, oil is pumped into the storage tank for storing; oil sediment by filtration and dirt oil separation, oil proceeds second settlement, dirty oil mixture proceeds clarification separation, Skim oil then be carried out a second settlement, sewage pumps to sewage treatment pond for dealing with.

6. Finished oil storage and transportation section: Finished crude oil is stored in storage tanks, the capacity of oil storage tank is two 1000 tons tanks, serve oil shed loading and issuing oil regularly to outside. Finished crude oil generally be stored and transported between at 32 ℃- 40 ℃, the working temperature of the palm oil should be at 50 ℃ to 55 ℃. to prevent overheating.

7. Fiber separation section: Press cake broken by breaking screw conveyor and then transported into the fiber separation air net and fiber polishing roller for fiber separating. The separated fiber material is sent to the boiler room as fuel; the separated stone is transported to stone warehouse by pneumatic conveying system for temporary storage.

8. Kernel recovery section: the stone needs intenerate tempering before being broken, the intenerating stone be divided into two or more petal by corrugated crusher, kernel was released. The broken mixture enters into broken mixture separation system; separation system adopts two stage separation and water separation. After separation, shell is sent to the warehouse for temporary storage, as boiler room fuel when necessary; the moisture content of separation kernel falls to below 7% through the hot air to dry. Dried kernel is sent to kernel storage warehouse for storing.

9. Sewage treatment section: the waste water has high organic matter content, biochemical oxygen demand BOD is about 25000ppm, required by qualified deal before emissions. Pool sewage treatment system is the most used and effective treatment. This treatment system is cost-effective, only needs adequate space, less investment costs.

FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Oil Mill Machinery Project

Sinoder Group Supply Whole set of Oil Grain Equipment:

1. 10-10000T/D Oilseed preliminary cleaning, drying, Storage section turn-key project

2. 10-5000T/D Oilseed Pretreatment, Pre-pressing production line turn-key project

3. 10-5000T/D Oilseed extraction production line turn-key project

4. 10-3000T/D Continuous Physical (Chemical) refining, fractionation production line turn-key project

5. 10-3000T/D Cold pressed peanut synchronization extraction protein powder under low temperature turn-key project

6. 10-1000T/D Phospholipid Concentrate Production line turn-key project

7. 10-500T/D Animal oil boil, refining, shortening and margarine turn-key project

8. 10-500T/D Biodiesel production line turn-key project

9. 10-1500T/D Cottonseed shucking project

10. 10-3000T/D Sunflower oil, rice bran oil, Corn, ect. oil pressing, refining, dewaxing turn-key project

11. 10-2000T/D Full automatic control filling packing production line turn-key project.

- 2019-09-07 » Palm Oil Physical Full Continuous Refinery Plant Exported to Nigeria

- 2019-07-10 » 400T/D Cottonseeds Flaking Roll Machine Exported to Uzbekistan by Old client

- 2018-05-08 » ZY/ZX Screw Oil Expeller

- 2017-12-11 » Congrats! Sunflower Oil ExpellerZX18 and Oil Refinery Plant Exported to Tanzania

- 2017-09-07 » Congrats! 150TPD Cottons Seeds Screw Oil Press Machine Exported to Africa Client

- 2017-06-05 » Screw Press Oil Machine Working Video for Industrial Production Oil Plant

- 2017-04-15 » Old Client from Algeria Ordered 2000PCS Egg Tray Making Machine and Oil Expeller

- 2017-02-18 » Video for 50T/D Oil Expeller and 15T/D Oil Refinery Plant Succeed in Operating

- 2017-02-18 » 2 Sets of Hydraulic Oil Press Machine Exported to Mexico

- 2016-09-28 » Delivery of 50T/D Oil Mill Plant to Old Client After 15T/D Oil Refinery Plant