Key Machines

Latest News

Oil Seeds or Fruit Preparation

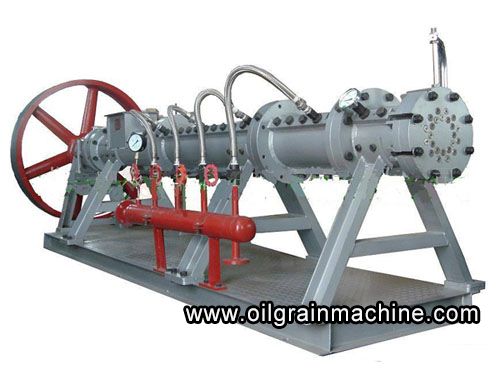

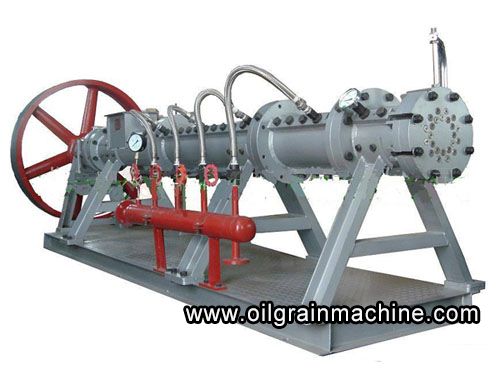

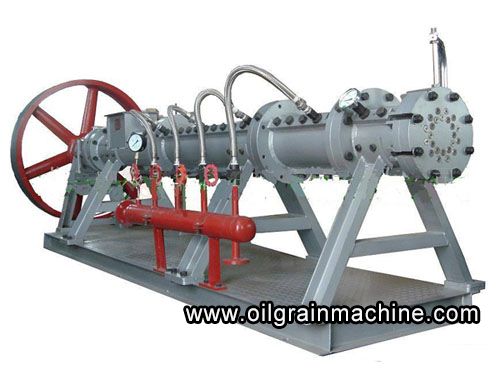

XLPH Extrusion Type Oil Plants Bulking Machine

The XLPH extrusion type bulking machine of company’s is suitable for various oil plants. The oil plants through the actions of exclusion, heating, shearing and kneading within cylinder of extrusion type bulking machine, make cell of oil plants destroyed thoroughly. Grease within cell exposed fully, and decompressed suddenly in template exit of extrusion type bulking machine.

We're here to help: Easy ways to get the answers you need.

Product Introduction

The XLPH extrusion type bulking machine of company’s is suitable for various oil plants. The oil plants through the actions of exclusion, heating, shearing and kneading within cylinder of extrusion type bulking machine, make cell of oil plants destroyed thoroughly. Grease within cell exposed fully, and decompressed suddenly in template exit of extrusion type bulking machine. Water vapor evaporated, so that gets proper and extruded material. As extrusion action makes solvent penetrated oil plants cell and makes grease leached from cell easier, to heighten efficiency of leaching and desolvation. For shorter persistence time in extrusion type bulking machine for oil plants, can protect quality of oil plants better

Usage:

It’s used for pretreatment for rice bran, maize germ, etc and various pre-pressing cake before leaching

Puffing Principle:

Raw embryo entered feed inlet of bulking machine by screw quantitative feeder through magnetic chute. Water vapor entered cylinder of bulking machine through direct steam throttle. Snaggletooth screw is made up of main screw axle rotated within cylinder of extrusion type bulking machine, and generate actions of mixture, extrusion, heating, shearing, kneading etc for materials. Materials extruded out from nib of template under high temperature and high pressure

Features:

1、Improving capacity, production efficiency can improve 30-50%

2、Improving product quality

3、Lowering energy consumption

4、Lowering residual oil within oil cake

Usage:

It’s used for pretreatment for rice bran, maize germ, etc and various pre-pressing cake before leaching

Puffing Principle:

Raw embryo entered feed inlet of bulking machine by screw quantitative feeder through magnetic chute. Water vapor entered cylinder of bulking machine through direct steam throttle. Snaggletooth screw is made up of main screw axle rotated within cylinder of extrusion type bulking machine, and generate actions of mixture, extrusion, heating, shearing, kneading etc for materials. Materials extruded out from nib of template under high temperature and high pressure

Features:

1、Improving capacity, production efficiency can improve 30-50%

2、Improving product quality

3、Lowering energy consumption

4、Lowering residual oil within oil cake

Technical parameters

XLPH Extrusion Type Bulking Machine Parameters

|

Model |

XLPH160 |

XLPH200 |

XLPH250 |

|

|

Extermal Dimension(m) |

3.5×1.25×1.5 |

4×1.25×1.5 |

5×1.3×1.8 |

|

|

Puffed rate |

1.2-1.4 |

|||

|

Capacity(T/D) |

High oil content |

50~80 |

120~180 |

180~280 |

|

Low oil content |

100~150 |

220~350 |

400~500 |

|

|

Power(kw) |

55 |

75/90 |

90/110 |

|