Key Machines

Latest News

Oil Filling Packaging Plant

Volumetric Filling Machine

Linear type Oil filling and capping machine

This filling machine adopts linear filling and integrative controlling of mechanics-electronics-pneumatics. It is of superior performance and the modeling complies with international mechanical design concept. It is mainly applicable to a variety of viscous, non-viscous, corrosive and non-corrosive liquids, and widely used in the quantitative small packages of vegetable oil, lubricants, chemical liquids, and daily chemical products, etc.

This filling machine adopts linear filling and integrative controlling of mechanics-electronics-pneumatics. It is of superior performance and the modeling complies with international mechanical design concept. It is mainly applicable to a variety of viscous, non-viscous, corrosive and non-corrosive liquids, and widely used in the quantitative small packages of vegetable oil, lubricants, chemical liquids, and daily chemical products, etc.

We're here to help: Easy ways to get the answers you need.

Product Introduction

Automatic Edible oil Filling machine is an extremely flexible filler capable of filling accurately and rapidly any viscosity liquids. Product delivery from your bulk tank to the pistons can be configured with a buffer tank utilizing a level-sensing float, a manifold with direct draw, or recirculation methods.

Oil Filling machine can be used for fixed amount small package filling,straight line type filling, metical, electric, apparatus control of all sorts of viscous and no viscous,erosive liquid,such as plant oil chemical,liquid,daily chemical industry.It is rather simple and rapid to change items,the design is quite distinct,the property is Very advantageous,its appearance corresponds to international concept for mechanical equipment.

Main Features:

1. Adopts piston pump to fill, suitable for all kinds of liquid, high precision; The structure of pump adopts shortcut dismantling organ, convenient to wash, sterilize.

2. The piston ring of volumetric injection pump use different material of silicone, polyclonal or other kinds according to liquid characteristic, use ceramic pump in special industry.

3. PLC control system, frequency conversion adjusting speed, high degree automation.

4. No bottle, no filling, auto count the quantity. And have the anti-drop device.

5. Filling quantity of all pumps is adjusted in a lump, minim adjustable for each pump. Easy and quick operate.

6. Filling head is equipped with anti-dropping equipment, diving to the bottom to fill, rise slowly, to avoid bubble.

7. The whole machine is suitable bottles in different size, easy adjusting, and can be finished in short time.

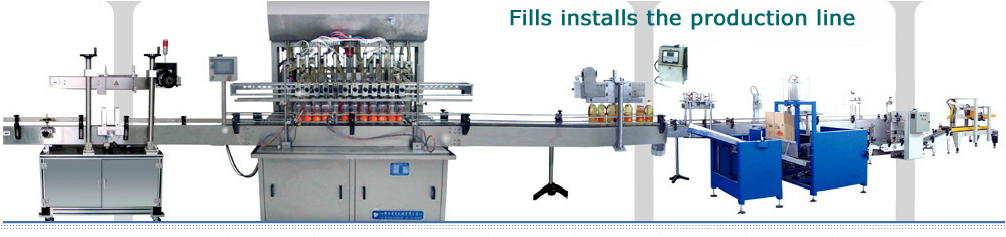

Labeling Machine & Oil Filling & Capping & Conveying & Ink-Jet Printing Machine & Sealing Machine and Conveying Line

Technical parameters

Oil Filling Machine Parameter:

|

Parameter |

Unit |

MODEL SNCY SERIES |

||||

|

Number of heads |

PCS |

12 |

10 |

8 |

6 |

4 |

|

Filling volume |

ML |

200-6000 |

||||

|

Productivity |

BPH |

1600-4000 |

1400-3200 |

1200-2600 |

1000-1900 |

720-1300 |

|

Filling tolerance |

% |

<0.5% |

||||

|

Power consumption |

KW |

1.5 |

1.5 |

1.5 |

1.2 |

1.0 |

|

Gas pressure |

MPA |

0.55-0.8mpa |

||||

|

Gas consumption |

M3/MIN |

1.6 |

1.4 |

1.2 |

1.0 |

0.8 |

|

Dimensions |

MM |

2000*1300*2800 |

2000*1300*2800 |

2000*1300*2500 |

2000*1200*2500 |

2000*1200*2400 |