Latest News

Animal Feed Processing

Animal Feed Making Plant Poultry Feed Pellet Production Line Machine

We're here to help: Easy ways to get the answers you need.

Product Introduction

Livestock Feed Pellet Line.

1) It is suitable for pig, swine, chickens, ducks, geese, quail and other animal feed processing and production.

2) The capacity range is 1-30 ton per hour. we will design based on your exact condition and demand. Possessing decades years of experience in poultry feed production line design and construction, we are capable of offer a tailor-made services and total solution.

Animal Feed Production Line

Feed Grinder →Feed Mixer → Feed Pellet Mill → Counterflow Cooler → Feed Pellets Crumbler → Feed Pellets Grading Sieve → Automatic Weighing and Packing Machine

1. Raw Material intake

All the solid ingredients packed in bags for feed production would be received in plant by road. Their materials will be store in store godown. According to requirement these material will be dumped manually in dumping hopper and conveyed to the pre-cleaner through the mechanical conveyor system.

2. Pre-Cleaning

Pre-cleaning is a process of removing unwanted material from our ingredients. As we received the material, there will be possibility of having unwanted material such as iron pieces, jutes threads, oversize pieces which can jam our silos system. So for cleaning we use a pre-cleaning machine. Then these pre-cleaned materials are transpired to silos through mechanical conveyors and elevators.

3. batching

Batching is process of combining each and every material in a proportioning ratio called feed formula it is very important process of every feed plant. A Better and accurate ration of material will give is a better quality and a fully nutrients feed. This batching process may be a computerized controlled or may have manual control room to cut the cost of the plant.

4. Grinding

Grinding is a process of bracking solid ingredients to a required size. Finer the material higher will be the surface area exposure to heat and moisture to accomplish the gelatinization in conditioning. A fine granding material can transfer his maximum energy to the animal as compare to a course grinded material. It is a very energy consuming process.

Animal Feed Hammer Mill Parameters

| Model | SFSP60×38 | SFSP60×45 | SFSP60×60 | SFSP60×75 | SFSP60×80 |

| Power(kw) | 30/37 | 45/55 | 55/75 | 75/90 | 90/110 |

| Output | 1-2(Fine) | 1.5-3(Fine) | 2-4(Fine) | 2.5-5(Fine) | 3-6(Fine) |

| 4-7(Coarse) | 6-9(Fine) | 8-12(Coarse) | 10-15(Coarse) | 12-18(Coarse) |

5. Mixing

As the name implies "Mixing" is a process of combining blending of micro ingredients. A proper mixing can be defined with a unit called co-efficient of variation. Smaller the co-efficient of variation higher will be the quality of mixing. Our well designed mixer machine has such a great quality. Beyond this is a mixer machine should have a provision to mix liquid to it as we need oil or molasses addition to the feed.

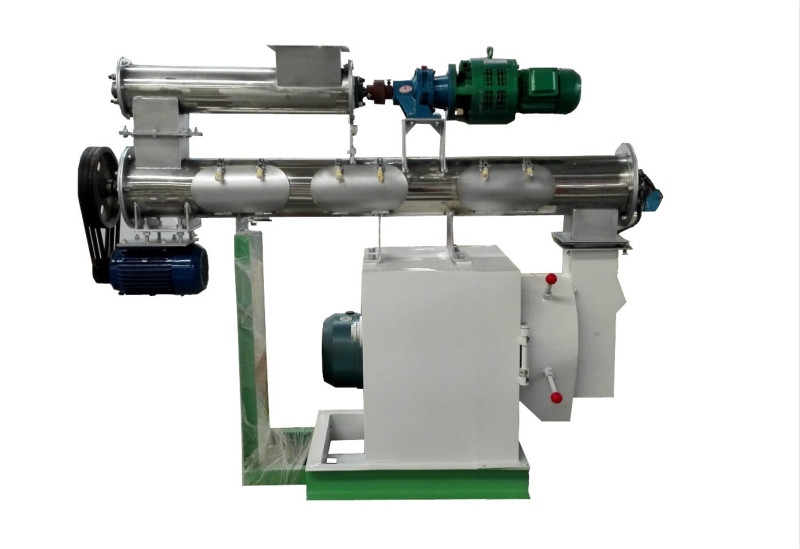

6. Feed Pelleting Mill

Pelleting is a main step of any pelleting plant. It is a process of converting any powder to solid shape called pallet. In this process the powder material is extruded through a well designed die with the help of rollers to convert it in to pallets. The quality & production of pallet mill depends on so many parameters.

1.Feed formula 2. Die configuration 3. Quality of Granding 4. Quality of conditioning. No doubt every material can be converted into pellets.

Animal Feed Plant Machine Parameters

| Model | Production capacity | Main engine power | Conditioner power | Conditioner diameter | Conditioner length | Feeder power | Inner diameters of ring die | Particle specifications |

| (t/h) | (kw) | (kw) | (mm) | (m) | (kw) | (mm) | (mm) | |

| SZLH350 | 2-5 | 55 | 4 | 350 | 3 | 1.1 | φ350 | φ2-18 |

| SZLH400 | 3-12 | 75/90 | 5.5 | 400 | 1.5 | φ400 | φ2-18 | |

| SZLH420 | 3-14 | 90/110 | 7.5 | 400 | 1.5 | φ420 | φ2-18 | |

| SZLH508 | 6-20 | 132/160 | 11 | 460 | 1.5/2.2 | φ508 | φ2-18 | |

| SZLH558 | 8-25 | 160/220 | 18.5 | 630 | 1.5/2.2 | φ558 | φ2-18 |

7.Feed cooling

Cooling is a process of removing heat. As we know during conditioning we add heat and moisture and also through palleting process heat generates by extrusion process. But the pallet should have a standard moisture and heat to attain its life of storage and make it safe from fungus. So we have to remove extra heat and moisture from the pallet. All this is done with the help of a well designed counter flow cooler.

8.Crumbling

Crumbling is a process in which pallets after cooling is broken in to small pieces to make it suitable for small chicks or hens. When there is no need of crumbling, we by-pass the feed directly to the screen with the help of By-pass Mechanism. A well designed crumbier should have capability to break the pellets without making much finer.

9. screening

Product coming out of crumbier is or their in pallets form (if we use by-pass) or in crumbs form. There are required to screen to remove fines and oversize particle. A double deck screeners are used to remove both fine and oversize particles. Fine and directed to pallet mill for repalleting while oversize particles are directed to crumbier for reprocessing. A well desired screener should have capability to remove fine and oversize to a desired percentages, And it should not be clog frequently.

10. Feed packing

The end of process in every plant is bagging also called packing. After screening the finished products are filled in to bags. In small and medium plants, bagging can be carried out manually but for higher production it is batter to go for electronic bagging machine.

Grease adding machine

Product features:

1、Apply to oil is added to the batch mixer, molasses, phospholipids and other nutrients, to adapt to the range.

2、Simple structure, automatic control, easy to operate.

3、If use weighing sensor measurement, high accuracy, can be up to 0.5%.

Automatic PLC Control System

With the automatic PLC control system, the animal feed processing line is with high efficiency and convenient operation.

1.Full automation of the complete production line

2.Constant product quality at a high throughput rate

3.Lower manpower requirements, less time cost

4.Better monitoring of the production process

The working process of animal feed plant is: 1. raw material cleaning, 2. Coarse and fine smash 3. Automatic batching. 4. high-efficiency mixing. 5. Conditioning 6. Granule maturation. 7. Cooling and drying. 8. Grading and product packaging.

Technical parameters

| No. | Name | Type | Qty. | Power (kw) | Performance&characteristics | ||||

| unit | total | ||||||||

| Materials receiving and handling system | |||||||||

| 101 | raw material hopper & screen | 2 | |||||||

| 102 | Induced fan | 4-72No | 1 | 3.00 | 3.00 | After balancing check; Smooth, low noise operation. | |||

| 103 | Pulse Bag Filter | TBLMb12 | 1 | ||||||

| 104 | Air lock | GFY210 | 1 | 0.75 | 0.75 | ||||

| 105 | Bucket elevator | TDTG3/23 | 1 | 2.20 | 2.20 | ||||

| 106 | Trommel screen | SCQY6 | 1 | 0.75 | 0.75 | High quality | |||

| Crushing System | |||||||||

| 202 | Storage bin for crushing | 2M3 | 1 | Made by 3mm steel plate. | |||||

| 203 | Induced fan | 4-72 | 1 | 3.00 | 3.00 | After balancing check;Smooth, low noise operation. | |||

| 204 | Pulse Bag Filter | TBLMb9 | 1 | ||||||

| 205 | Settle down chamber | 1 | Made by 3mm steel plate. | ||||||

| 206 | Locked screw conveyor | TLSB20 | 1 | 1.50 | 1.50 | ||||

| 207 | Impeller feeder frequency | TWLY25*40 | 1 | 1.10 | 1.10 | ||||

| 208 | Water type crusher | SWSP63*6 | 1 | 45.00 | 45.00 | ||||

| 209 | Bucket elevator | TDTG36/2 | 1 | 2.20 | 2.20 | ||||

| Mixing System | |||||||||

| 301 | Silo for mixing | 2M3 | 1 | Made by 3mm steel plate | |||||

| 302 | Pneumatic gate | TZMQ25×25 | 1 | Nice sealing | |||||

| 303 | Double shaft mixer | SLHSJ1.0 | 1 | 11.00 | 11.00 | ||||

| 304 | Silo | 1M3 | 1 | Made by 3mm steel plate | |||||

| 305 | Bucket elevator | TDTG36/2 | 1 | 2.20 | 2.20 | ||||

| 306 | Pneumatic tee | ||||||||

| 307 | Magnet drum | TXCT20 | Iron removing≥99.5% | ||||||

| 308 | Automatic feeding device | ||||||||

| Pelleting System | |||||||||

| 401 | Storage bin for pelleting | 2M3 | 1 | Made by 3mm steel plate. | |||||

| 402 | Pellet mill | SZLH350 | 1 | 55+ 2.2+0.75 |

57.95 | ||||

| 403 | Airlock | GFY21 | 0.75 | 0.75 | |||||

| 404 | Counterflow cooler | SKLN15×15 | 1 | 1.50 | 1.50 | ||||

| 405 | Pellet crusher | SSLG15×100 | 1 | 5.50 | 5.50 | Low energy consumption, more uniform particle size, grade back less material, low noise, high efficiency. | |||

| 406 | Draught fan | 4-72No5A | 1 | 11.00 | 11.00 | ||||

| 407 | Material discharge | XL100 | 1 | ||||||

| 408 | Airlock | GFY210 | 0.75 | 0.75 | |||||

| 409 | Bucket elevator | TDTG36/2 | 1 | 3 | 3 | Same with Item 105. | |||

| 410 | Rotary sifter | SFJH100×2 | 1 | 1.50 | 1.50 | Import elastic support plate,Direct drive belt and low noise;Internal flow line design, no material deposition, no cross-contamination. | |||

| Packaging System | |||||||||

| 501 | Level indicator | 2 | |||||||

| 502 | Product silo | 4m³ | 1 | Made by 3mm steel plate | |||||

| 503 | Buffer hopper | 1 | |||||||

| 504 | Automatic packing machine | HL-CS-50 | 1 | 1.5 | 1.5 | ||||

| Auxiliary system | |||||||||

| 601 | Oil adding system | 1 | 1.50 | 1.50 | Microcomputer control, automatic quantitative filling, error ≤1%. | ||||

| 602 | Add liquids add pipeline accessories system | 1 | |||||||

| 603 | Air compressor and pipe system | 7.50 | 7.50 | ||||||

| 604 | Steam boiler and pipes system | 1 | |||||||

| Control System | |||||||||

| 701 | Control cabinet | ||||||||

| 702 | Cable, wire, wire trunking, and other supporting materials | ||||||||

| Installation materials | |||||||||

| 801 | Suction, dust, cooling air network system | ||||||||

| 802 | Steel, platform, stair handrail | ||||||||

| 803 | Seals, piping materials and other non-standard parts | ||||||||

| 804 | Electrode, oxygen, gas | ||||||||

| 805 | Pneumatic components | ||||||||

| 806 | Paints | ||||||||

Reference Solution for Animal Feed Processing Plant

|

Main Machine & Capacity |

1-2 t/h |

3-5 t/h |

6-8 t/h |

10 t/h |

20 t/h |

|

Feed hammer mill |

SFSP56 × 30 |

SFSP56 × 40 |

SFSP56 × 60 |

SFSP66 × 80 |

SFSP112 × 4 |

|

Feed pellet machine |

SZLH250 |

SZLH320 |

SZLH350 |

SZLH420 |

SZLH508 |

|

Mixer |

SLHY1.0 |

SLHY1.0 |

SLHY2.0 |

SLHY2.0 |

SLHSJ3.0 |

|

Cooler |

SKLN11 ×11 |

SKLN15×15 |

SKLN15 ×15 |

SKLN19 ×19 |

SKLN22 ×22 |

|

Crumbler |

SSLG22 ×40 |

SSLG15 ×100 |

SSLG15 ×100 |

SSLG24 ×110 |

SSLG24 ×16 |

|

Rotary screener |

SFJH80×2d |

SFJH100×2d |

SFJH100×2d |

SFJH130×2d |

SFJH150×2d |

|

Cooling fan |

4-72No4A |

4-72No5A |

4-72No5A |

4-72No8D |

4-72No8C |

|

Cooling discharger |

XL60 |

XL80 |

XL90 |

XL120 |

XL150 |

|

Boiler |

LSG-0.3-0.4 |

LSG-0.3-0.4 |

LSG-0.5-0.4 |

LSG-1.0-0.7 |

LSG-1.0-0.7 |

|

Lifting equipment |

TDTG26×18 |

TDTG26×18 |

TDTG36×23 |

TDTG36×28 |

TDTG50×23 |

|

Outline dimension |

9×3.5×11m |

9×3.5×12m |

12×4.2×13.5m |

13.5×4.8×14m |

15×5.5×17m |

FAQ

The planning and design for whole factory or complete set production line

1. Poultry & livestock feed mill project:

· Feeds for animals in various growing period;

· Different capacity, 0.5~40TPH per line;

· Meeting the standards of different countries and regions.

2. Aqua feed mill projects:

· Sinking fish feed, shrimp feed etc.

· Different capacity, 0.3-15 TPH per line;

· Meeting the standards of different countries and regions.

3. Premix plant project:

· Specialized equipment and process flow;

· Effectively controlled cross contamination, residue and dust emission;

· Different capacity, 0.3-15 TPH per line.

4. Pet-food plant project:

· Specialized extruder, dryer and coater adopted;

· Different capacity, 0.3-10 TPH per line.

Animal Feed Pellets Mill Products Instruction:

Extra-fine 1.5 mm grinding tools are used for breeding miniature birds and aquatic animals. Such as: (shrimp, crab, small fish and other aquaculture).

2.0 mm grinding tools is used for breeding: parrots, thrushes, birds and other pet birds.

2.5 mm grinding tools are used for breeding: young rabbits, young chickens, ducklings, goslings, young birds, young birds, young peacocks, young aquatic fish and other small animals.

3-4 mm grinding tools is used for breeding: rabbit, chicken, duck, goose, pigeon, bird, peacock, aquatic fish, etc

5-6 mm grinding tools is used for breeding: pigs, cattle, samples, dogs, horses and other livestock.

If you're interested in our feed pellet machines, please kindly tell us the following requirement:

1. What's the feed pellet production capacity do you want?

R:we can supply feed pellet mill or production line with output from 0.1-30t/h.

2. What's your feed raw material and size and feed formula content?

R:Tell us feed material formulation,then we can design the suitable production line based on actual demand.

3. What's the final feed pellet diameter or size do you want or for what animal?

R:Our equipment can produce feed pellet diameter 2-8mm,for chick feed,we can produce crumb feed particle.

for chicken? cow? sheep?fish?horse? cow? or pig?or what purpose?

4. What's your country industrial electricity voltage?

R:General standard motor in China work under 380V,50Hz,3Phase,if not match,tell us we can modify motor.